ITS ePrimer

Module 15: Port Operations

Authored by WSP USA Inc.

2019

Table of Contents

Purpose

The purpose of this module is to provide an overview of Intelligent Transportation Systems (ITS) related to port operations. This module also is intended to facilitate the expansion of United States (U.S.) port participation in the development, implementation and operations of ITS projects regionally, and in a port environment. Readers will gain a greater understanding of the key elements involved in planning, evaluating, financing, and deploying ITS projects that can address congestion and other transportation network challenges experienced by ports.

Return to top ↑

Objectives

After completing the module, you should be able to:

- Understand the planning, feasibility, financing and deployment processes involved in implementing ITS projects within the port area and the transportation network connecting the surrounding region.

- Describe how ITS technologies can improve the safety, mobility, efficiency, security, and sustainability of port operations.

- Recognize the complex and distinct operational needs of the various port community stakeholders while identifying and assessing ITS alternatives.

- Identify public and private sector funding sources that can support the implementation of ITS projects, while leveraging existing port assets.

- Describe example ITS projects implemented within a port area transportation network and surrounding region and the benefits they have conferred to stakeholders.

Return to top ↑

Introduction

In response to sustained growth in freight movements through their facilities, many ports have increased operational capacities without greatly changing landside boundaries or improving regional transportation connections. This has led to increased levels of congestion on the surrounding inland distribution network, impacting the safety and efficiency of freight and passenger movements, as well as overall mobility for all travelers.

Along with building additional road and rail supporting infrastructure at significant cost, ports have opportunities to use their transportation assets more intelligently and efficiently through the application of ITS. With this in mind, the American Association of Port Authorities (AAPA), the U.S. Department of Transportation (USDOT) Maritime Administration (MARAD) and the ITS Professional Capacity Building (PCB) Program organized a team of U.S. port industry experts to assist in the development of this module on ITS for ports.

Ports are origins and destinations for truck- and rail-based freight movement. Port transport systems are bound, typically dead ends or local circulatory loops. Trucks and trains visit ports only for freight exchanges. Ports are tightly regulated spaces where private and public entities both cooperate and compete. Thus, implementation of ITS in a port environment requires consideration of a range of factors not typically considered for traditional ITS locations.

For this module, a port is defined as a single- or multiple-facility entity that enables the transfer of cargo and/or passengers between logistically-linked transport modes (e.g., truck to barge to ocean-going vessel). Facilities at a port can include marine, intermodal, and inland terminals, container transfer facilities, and logistics depots. A port may provide services at inland multimodal facilities as well as along navigable waterways. In addition, the term port owner throughout this module encompasses port authorities, terminal operators, private companies, and project sponsors that own and/or operate a port.

Since ports have complex interactions with an amalgam of public and private entities, each with varying interests in the application of technologies, this module addresses the implementation of ITS projects from three perspectives:

- Local/regional – Applications of ITS for the surrounding road and rail network that indirectly impact port operations. This could include the provision of freight signal priority (FSP) on road and rail interchanges in proximity to a terminal.

- Port specific – Applications of ITS for the port area transportation network, such as terminal roadways, gate access management, and reservation systems.

- Combination – Applications of ITS that addresses port operations, the port area transportation network and the region. This could include a truck staging and parking application that provides staging information at the terminal, and detailed route information for efficient and timely access to the facility.

It is important to understand the distinction between these perspectives as the planning, feasibility, financing and deployment processes for each may have subtle differences. For example, activities for planning, developing and implementing a regional FSP would likely involve a cross-section of other stakeholders (e.g., state or local departments of transportation that operate the roadways, metropolitan planning organizations (MPOs) that plan and program funds). Whereas a gate access management and/or reservation system may only include involvement of the port authority, terminal operator and the trucking companies operating at the port. The span of communication, collaboration and cooperation is driven by the proposed ITS project.

Return to top ↑

ITS Advancement in Ports

The advancement of ITS in the port industry has been enabled by:

- the rapid development and availability of cost effective technologies that maximize the use of existing transportation assets, and

- the need for service improvements to address a range of operational challenges that occur during (recurring) and disruptive (nonrecurring) conditions.

Enabling Technologies

Technologies often support multiple functions in port operations, including data collection, network surveillance, asset tracking, communications, and information dissemination. Technologies that commonly enable ITS functions in ports are listed in Table 1.These technologies are grouped into the following classes that reflect their general role in the integrated implementation of ITS, port, and terminal functions:

- PX: Proximity and Detection Systems

- ID: Cargo and Vehicle Identification Systems

- VI: Vehicle Information Systems

- LO: Location Determination Systems

- CO: Wideband Communications Systems

- LG: Logistics Management Systems

Table 1: Enabling Technologies and their Use in Ports

| Technology |

Example of Use in Ports |

Class |

| Cameras and Sensors |

A technology that uses cameras and sensors to capture images and other supporting input, extract application-specific information, generate descriptions, and make decisions as part of an intelligent system.

Cameras and sensors provide critical input not only for autonomous vehicle on the road, but also for security and condition monitoring in the port. They also assist in gate transactions, improving efficiency by making the process faster. |

PX |

| Radio Detection and Ranging (RADAR) and Light Detection and Ranging (LIDAR) |

RADAR and LIDAR are distance determining technologies that work similarly except LIDAR emits pulses of light and RADAR emits pulses of radio waves. The signals bounce back from an obstacle and the instrument measures the return times and wavelengths. These technologies can also detect the angle and velocity of surrounding objects, and determine brake lights and changing road conditions.

RADAR and LIDAR are heavily used for autonomous vehicles and will help in development of autonomous trucks for cargo hauling. |

PX |

| Optical Character Recognition (OCR) |

An electronic system that recognizes printed or written text characters in a digital image taken by intelligent / digital cameras. OCR systems allow users at a remotely located computer terminal to rapidly and accurately capture information that can be compared to a predefined list of targets.

OCR is used for asset identification. For instance, OCR systems are used to identify incoming and outgoing containers based on their ISO numbers.

OCR is also used to automate data transfer at marine facilities by filtering, aggregating, and formatting data before presenting it to a host system. The combination of a Gate Operating System (GOS), Terminal Operating System (TOS), and OCR at a port helps assign accurate work assignment to over-the-road (OTR) trucks entering the terminals for cargo delivery or receipt. |

ID |

| License Plate Recognition (LPR) |

LPR systems use OCR to read and analyze the license plates of incoming and outgoing vehicles at the facility gate. LPR systems first look for the presence of a license plate, then extract its associated numbers and letters. Data extracted by a LPR system can be stored, linked to other applications, or compared to information in a database.

LPR systems are used to read and analyze the license plates of incoming and outgoing vehicles at the facility gate. The information gathered is matched with a database to help complete the gate transaction faster than a manual procedure. |

ID |

| Radio Frequency Identification (RFID) |

A technology that uses radio waves to automatically identify and collect information from cargo vehicles entering or leaving a facility, cargo handling equipment, and to record where cargo is placed in the storage yard. One method of object identification is to attach a microchip or “tag” equipped with memory and an antenna, holding a unique identity number and other information. RFID has helped convert manual processes to automated processes, such as gate operations, in which truck wait times are reduced. |

VI |

| Weigh-in-motion (WIM) |

A sensor technology used to determine characteristics of a moving vehicle such as gross vehicle weight, wheel loads, axle loads and speed. WIM sensor devices are typically embedded in the pavement surface.

At ports, WIM devices are deployed in gate lanes along with other technologies, such as OCR and RFID, to connect vehicle and cargo weights with transaction data. In the case of container cargo, WIM helps enforce International Maritime Organization’s (IMO) Safety of Life at Sea (SOLAS) container weight regulations. |

VI |

| Vehicle Telematics |

Telematics devices provide information on a vehicle’s or equipment’s condition, find optimal delivery routes, monitor dangerous driving habits, track the location of drivers and cargo, and improve idle trailer allocation.

Telematics devices are used to obtain information on the condition of a vehicle’s mechanical components. This information helps fleet managers determine whether a vehicle requires maintenance or repair, find optimal delivery routes, monitor dangerous driving habits, track driver and container locations, and improve idle trailer allocation. |

VI |

| Electronic Logging Devices (ELD) |

A technological device that is attached to a commercial vehicle to monitor a vehicle’s or equipment’s engine, capture data on whether the engine is running, miles driven, and duration of operation. |

VI |

| Geographic Positioning System(GPS) |

A satellite-based global navigation and positioning system that is composed of satellites, ground stations, and receivers. By collecting signals from at least three satellites, GPS receivers pinpoint a user’s location within 10 to 15 feet.

GPS is the foundation of other ITS technologies such as Geographic Information Systems (GIS), and ELDs used by the maritime community. GPS can additionally be used to track container handling equipment and the placement of containers. |

LO |

| Differential GPS (DGPS) |

A technology used to provide positional corrections to GPS signals. DGPS systems use a fixed, known position to adjust GPS calculations in real time. In doing so, DGPS systems improve the accuracy of position data provided to the user.

DGPS is needed for equipment tracking and inventory control systems to safely operate with sufficient precision. In ports, DGPS technology is used for tracking cargo and equipment within the port, as well as equipment automation. |

LO |

| Bluetooth Tracking |

A technology that passively reads carrier signals from passing devices equipped with active Bluetooth hardware, such as smart phones.

Bluetooth tracking is used to track street truck movement in, out, and within a terminal. Bluetooth proximity beacons are used to track cargo movement through various nodes. |

LO |

| Cellular Communication |

A communications system that is composed of cell towers and cellular devices. By collecting radio signals from multiple cell towers, an approximate cellular device location can be established and data can be exchanged between vehicles, infrastructure and travelers.

Cellular communication technology, including 5G cellular, is used to track the location of vehicles and handling equipment, and associated cargo. |

CO |

| Dedicated Short Range Communications (DSRC) |

A wireless communications technology used for close-proximity communications between vehicles and the immediate infrastructure. It supports location-specific communications for ITS capabilities such as vehicle management, driver information, and automated commercial vehicle operations. One of the types of architecture interconnects defined in the Architecture Reference for Cooperative and Intelligent Transport (ARC-IT).

DSRC can be used to enable trucks carrying cargo to utilize adaptive cruise control, clear vehicles entering and exiting a maritime facility, and to issue in-vehicle warnings. |

CO |

| Electronic Data Interchange (EDI) |

The automated transfer of information by computer systems using a standard format. EDI replaced postal mail and fax with email and databases to allow for faster and streamlined data exchange of all business documents. EDI allows participating organizations to generate, receive, and process data with little or no human intervention.

EDI is used to securely transfer goods movement data between liners, beneficial cargo owners (BCOs), truckers, railroads and government agencies including Customs and Border Protection. |

LG |

| Internet of Things (IOT) |

A network of physical objects that feature an IP address for internet connectivity, and the communication that occurs between these objects and other Internet-enabled devices and systems. The IoT extends internet connectivity beyond traditional devices like computers, smartphones and tablets to a diverse range of devices and everyday things that utilize embedded technology to communicate and interact with the external environment, all via the Internet.

IoT is used to connect multiple platforms such as TOS, Port Portals, autonomous vehicles, etc. to share real-time information, enabling better cargo routing decisions. |

LG |

| Cloud-Based Data Processing and Management |

A data processing system that involves performing complex computing for massive amounts of data. It eliminates the need of expensive hardware and real estate space as data is saved and retrieved over the internet (“the cloud”). Using cloud-based computing, data processing can be performed in real-time and at a faster rate.

Cloud-based data processing and management are used to make cargo data, such as vessel stowage plans, available on a controlled basis across the port user community. The technology is additionally used to automate electronic booking, the digital transmission of shipping instructions, and real-time container-status tracking. |

LG |

| Blockchain |

A digital database or ledger that can be programmed to record interactions between and across multiple parties. Blockchain technology can be used to convert the documents, information, and commitments associated with international trade into a series of digital transactions based on permissions and secure encryption. The digitization of data makes it more visible to stakeholders, such as shipping carriers and trucking companies, thereby allowing them to efficiently plan their operations.

Blockchain technology can be used to track freight, streamline the bill of lading process, execute bookings, and to submit shipping instructions and trade compliance documentation. |

LG |

Source: WSP USA

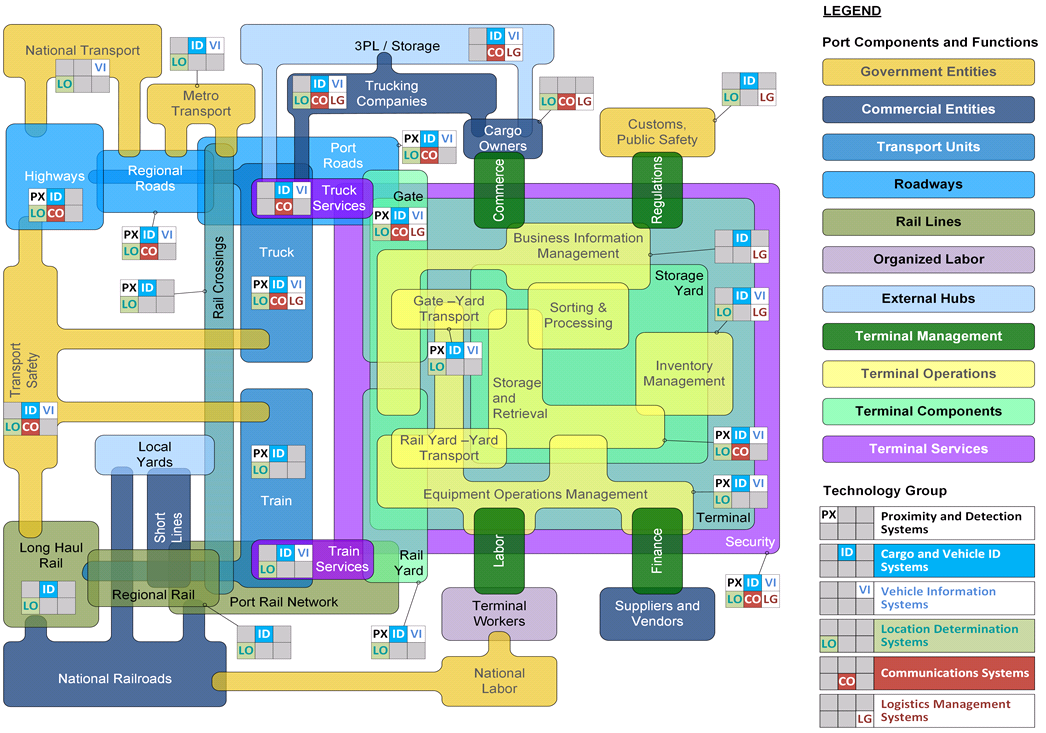

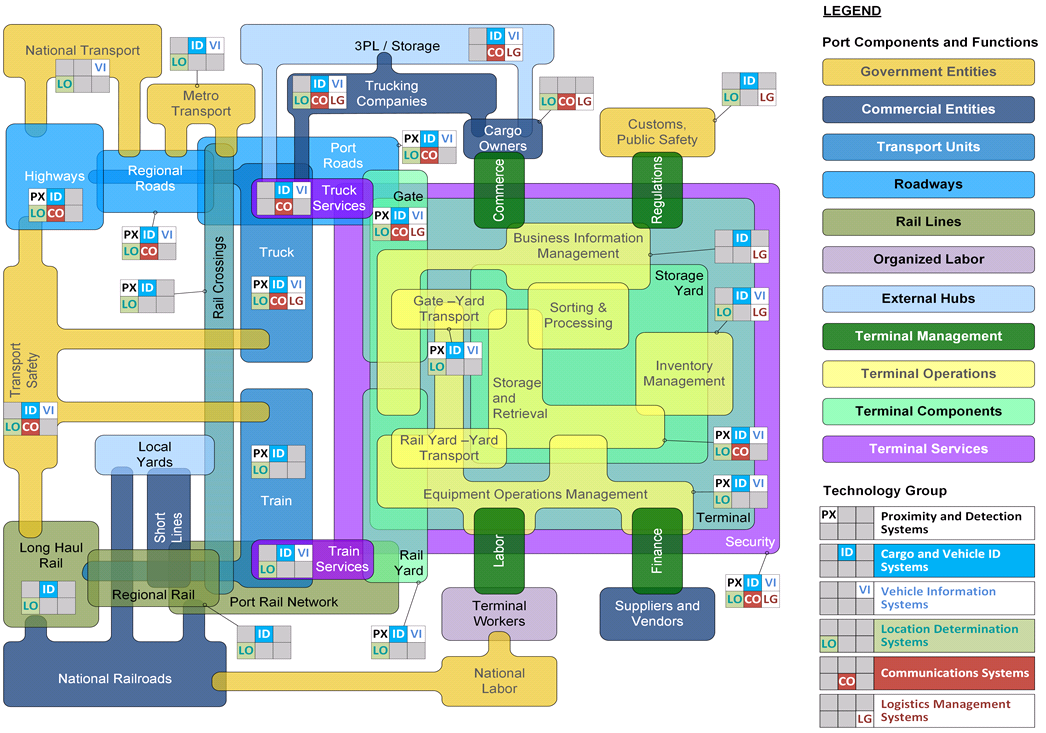

Figure 1 presents the logical relationship between the major elements of a port, its landside connectivity, its operating components, and the entities with which it interfaces. Shape overlaps reflect interactions between elements. Wherever ITS technologies might have a role or influence, an icon indicates those technology classes that are likely to be deployed in support of more efficient and safer operations.

Figure 1: Port Interactions and ITS Technologies

Source: WSP USA

(Extended Text Description: The figure illustrates the complexity of port interactions with various stakeholders, infrastructure systems, and ITS technologies. The figure covers interactions between the following stakeholders; government entities, commercial entities, organized labor, and external hubs. The figure covers the following infrastructure systems; transport units, roadways, rail lines, terminal management, terminal operations, terminal components, and terminal services. The figure covers the following ITS technologies; proximity and detection systems, cargo and vehicle ID systems, vehicle information systems, location determination systems, communications systems, and logistics management systems.)

ITS Applications

A range of ITS applications are under development or have been developed and implemented to enhance the movement of freight within the port area transportation network and in the surrounding region.

Local/Regional

Connected, Automated and Autonomous Vehicles: Incorporate connectivity, automation and/or autonomy to allow vehicles to operate in some or all aspects without human assistance. Automated vehicles can provide a path for ports to further explore automated terminal equipment and autonomous freight delivery.

Source: USDOT

Platooning Systems: Platooning systems link vehicles in a convoy using connectivity technology and automated driving systems. Linked vehicles follow each other closely with the vehicle at the front of the platoon acting as its leader. Vehicles behind the leader automatically react and adapt to changes in the lead truck’s movement. This technology can be used at ports to improve traffic flows by consolidating vehicles heading to the same destinations.

Route Guidance: Navigation applications can identify the fastest path through the roadway network for ingress to or egress from the port. If combined with terminal turn time reporting, a trucker could identify the optimal timing and route to their destination.

Port-Specific

Intelligent Recognition and Imaging Software (IRIS): IRIS is an application that uses OCR and RFID to recognize and track containers, trains, trucks, and license plates through marine terminals and ports. IRIS is based on a neural network image processing algorithm that allows it to extract the relevant information from an asset, typically a container. IRIS data is used to compile a library of traits and subsequently to extrapolate the systems recognition ability.

Equipment Tracking System (ETS): An ETS keeps track of handling equipment thereby allowing more efficient deployment in response to competing demands. ETS can be comprised of DGPS, RFID, inertial and Bluetooth tracking systems. At marine terminals, ETSs are used to track the movement of cargo handling equipment such as straddle carriers, gantry cranes, lift trucks, etc.

Port of Halifax Terminal Gate Metrics Module

The Port’s Terminal Gate Metrics module provides vital information on the fluidity of truck gates at the facility by providing current and historic information on gate wait time, and truck service time. The Port makes this data publicly available and in doing so can reduce congestion and greenhouse gas emissions.

The Port gathers its data from the Halifax Harbor Bridges MacPass electronic tolling system. Most vehicles in the area have MacPass transponders that are detected by the Port’s MacPass readers as vehicles pass various checkpoints. Checkpoints are placed at terminal inbound gates, terminal outbound gates, and certain upstream locations to create a holistic picture of vehicle movement. This data is subsequently analyzed to determine gate wait time, and truck service time.

The data gathered from the Port’s readers present a representative sample of trucks entering and exiting its marine container terminals. The data is color coded and presented in an understandable way.

Terminal Operating System: A TOS is an application designed to manage the movement, processing and storage of cargo in and around a marine terminal or port, along with all the data required to satisfy all commercial, business, and regulatory requirements. A TOS typically includes a large database management system (DBMS) and integrates data flows with other technologies such as RFID, OCR, GPS, DGPS, WIM, etc.

Gate Operating System: A GOS is designed to manage the movement and processing of cargo through a port’s terminal gate. A GOS interfaces with multiple technologies such as OCRs, RFID, WIM and LPR to process information for cargo arrival and departure. GOS has helped convert tedious and time consuming manual procedures into efficient and accurate automated and paperless gate processes.

Terminal Status Reporting: Terminals may offer data portals that report the condition of their facilities. These reports may include empty container availability, chassis availability, terminal area closures, expected service changes, special security requirements, and truck cycle times.

Gate Queue Reporting: Using technologies such as geo-fencing and automatic truck position reporting, business applications track and report truck populations in gate queues through smartphone applications that estimate wait times.

Truck Appointment Systems: An appointment system allows cargo owners and trucking companies to make appointments to carry out marine terminal transactions within given time windows. This allows drayage firms to make efficient dispatching plans and lets marine terminals control workloads. Also known as a Truck Reservation System (TRS). The Port of Virginia’s TRS has improved productivity at its Norfolk International Terminal and Virginia International Gateway by reducing truck turn times up to 32 percent.

Street Exchange Systems: In a street exchange system, empty containers are transferred directly from the importer’s trucker to an exporter’s trucker. This is generally carried out through secure internet applications that integrate data and document commercial and liability transfer between liners, BCOs, and drayage operators.

Automated Work Flow: Automated work flow is currently used with EDI. At ports, automated work flow data models can be used to streamline inbound and outbound cargo processing. Automated work flow is also applied in automated gates to support faster transactions.

Combination

Geo-fencing: A geo-fence is a virtual geographic boundary that is created around a facility or area using GPS or other tracking technology. The geo-fence can track, record, and trigger a reaction when mobile devices, such as RFID tags or Bluetooth antennas, cross the boundary. Geo-fencing has several applications at port facilities, including determining truck turn times, gate or street queue populations and monitoring truck traffic within specific boundaries of the port area transportation network.

Freight Signal Priority: Signals at arterial road intersections and exit gates can be timed to control flow through the port and into gates, channeling queues and preventing blockages at signalized intersections. In some ports, FSP systems, combined with dedicated routing lanes, help channel truck flow and avoid adverse mixing with non-port traffic. Also known as Freight Vehicle Priority.

Rail Yard Integration: Rail crossing controls can be integrated with roadway signals and port-wide monitoring systems to provide smoother and safer movement of trucks and trains across the port’s transportation networks. Rail operations management can be integrated with maritime and truck operations to allow intelligent scheduling of rail, truck, gate, and terminal resources.

Port of NY/NJ Terminal Information Portal System (TIPS)

Launched in September 2015, the Port of NY/NJ TIPS is a single consolidated web portal that compiles information from all six container terminals and make the data available to qualified users in real-time over the Internet. The system presents Port and terminal related information, container availability, booking status, vessel schedules, and empty container return locations.

The Port’s TIPS is a part of its broader Port Community System, which integrates a range of operational information and customer support into its platform. The system has the following functions:

- Make information, e.g. booking inquiries and vessel schedules, readily available to stakeholders;

- Centralize the storage and dissemination of terminal information;

- Create ‘watchlists’ of containers regardless of what terminal they are being handled at;

- Notify stakeholders of container or booking status changes;

- Meter truck arrival rates while keeping resources for all stakeholders operating at maximum levels.

Benefits of the ports TIPS include:

- Decreased truck congestion;

- Reduced idling and emissions;

- Improved terminal productivity; and

- Quicker response times to operational issues.

Port Community System (PCS): Some ports have deployed applications that bring together all port, liner, drayage, BCO, terminal operator, and ITS streams. These portals are a central web site that helps users determine cargo availability and export booking status, and obtain information on terminal-specific operations, vessel schedules, and container locations. It also helps trucks by providing information regarding chassis and empty container availability. The Port of New York and New Jersey has deployed a “Terminal Information Portal System” (TIPS) as part of its PCS, and the Port of Los Angeles and GE Transportation have deployed a PCS, known as “Port Optimizer”, which uses cloud-based technology to provide system wide information.

Freight Advanced Traveler Information System (FRATIS): FRATIS is a bundle of connected vehicle applications that provides freight-specific dynamic travel planning and performance information. FRATIS provides users with real-time data on congestion, travel times, and incidents along freight routes and at freight facilities, which allows vehicles to be optimally and dynamically routed. FRATIS is used to optimize drayage operations so that load movements are coordinated between freight facilities to reduce empty-load trips.

Traveler Information Reporting: Existing ITS systems report traffic, weather and parking conditions through mobile devices, in-vehicle systems, online services such as 511 and roadway infrastructure such as dynamic message signs (DMS). These applications can report traveler conditions along with information integrated from terminal status reporting and gate queue reporting applications.

Vehicle to Everything (V2X) Communications

Technologies that enable ITS functions in ports are very similar to those for freight-related ITS applications. Module 6, “Freight, Intermodal, and Commercial Vehicle Operations (CVO)” provides a description of ITS freight technologies and communications architecture, including long-range, wide-area mobile communications and short-range, fixed infrastructure-to-vehicle communications.

While ITS involves a variety of advanced applications that extend beyond vehicle systems, Port ITS projects are primarily supported by the following bi-directional, real-time V2X technologies that allows vehicles to communicate with other vehicles, devices, infrastructure, and the Internet of Things (IoT).

- Vehicle-to-Vehicle (V2V) enables freight vehicles (trucks, trains, and cargo handling equipment) to communicate with each other and other vehicles in the vicinity via advanced communication systems such as DSRC and 5G cellular. It allows the vehicles to share vehicle type, identity, position, speed, heading, transaction data and other information with each other.

- Vehicle-to-Device (V2D) enables freight vehicles to communicate with receiving devices such as RFIDs, LPR, OCR, etc. V2D services can help streamline information flow for incoming and outgoing freight vehicles. V2D and V2V in combination can help in safe transport of cargo on road and movement within a cargo terminal.

- Vehicle-to-Infrastructure (V2I) enables freight vehicles to communicate with roadway, rail and port infrastructure, such as traffic signals, railroad crossing, cargo terminal gate system, and priority lane systems (also known as Road-Side Units or “RSUs”). V2I service can use both DSRC and cellular network for communication.

- Vehicle-to-Internet of Things (V2IoT) enables freight vehicles to communicate to multiple technologies via IoT. Any type of information can be uploaded using cloud computing and can be retrieved to analyze and make informed decisions. V2IoT service can assist in V2I/I2V service as well.

IoT enables communication between supply chain instruments, connecting ports, carriers, warehouses and distribution centers, BCOs and customers. With further development and broad participation, IoT platforms can optimize the exchange of logistic information and offer holistic improvements to the supply chain network.

Port ITS Benefits

ITS can improve port performance by enhancing the safety, mobility, efficiency, and visibility of terminal assets, cargo and entities involved in the system (see Table 2).

Table 2: Port Service Improvements from V2X and IoT Communications

| Service Improvement |

V2X and IoT Communications Technology |

| Vehicle / Vehicle |

Vehicle / Infrastructure |

Vehicle / Device |

Vehicle / IoT |

IoT Platform |

| Safety and Reliability |

Avoid port-area collisions, goods movement accident losses, hazardous material releases. |

| Port equipment position and routing. |

Speed constraints, variant road conditions, construction areas, queue conditions, congestion, weights in motion. |

Downstream congestion, speed reduction warnings, signal conditions, rail crossing condition, truck trailer basic safety message. |

Trip timing or routing to avoid incidents, hazardous material conditions, expected rail movements and road blockages. |

Vehicle maintenance tracking, inspection tracking and reporting, driver / vehicle qualifications. |

| Resilience |

Mitigate the impact of disruptive events, such as extreme weather or geological events. |

| Engine conditions / flooding, mass vehicular stalls, emergency vehicle movements / warnings, utility vehicle proximity. |

Road, rail, tunnel, and bridge closures; route damage; route reversals / alternatives. |

Freezing / icing, stream conditions, power grid conditions, signal system disruption. |

Rerouting directions, evacuation warnings, loss-of-service messages, emergency transport protocols. |

Impact predictions, weather paths, flood surge modeling, seismic damage mapping. |

| Cargo Visibility and Reliability |

Improve the reliability and timeliness of cargo transport, and improve the responsiveness of service providers. |

| Peloton / convoy, multi-shipment manifest coordination, trailer size/ configuration. |

Weights and weight limitations, construction areas, operational conditions that increase delays, truck parking tracking. |

Vehicle characteristics, shipment location, transport unit location and condition, geofencing, net velocity, driver safety conditions, truck parking info. management system (TPIMS) availability. |

Route recalculation, scheduled route interruptions, vehicle / signal synchronization, variable priority movements, TPIMS synchronization. |

Congestion tracking and projection, route balancing and load sharing, dynamic proactive route optimization, TPIMS optimization. |

| Vehicle Efficiency and Mobility |

Reduce travel time, reduce queueing and idling, maintain network fluidity, and improve transport workforce efficiency. |

| Peloton coordination, driver load splitting, driver team condition / coordination. |

Signal pattern reporting, speed monitoring, geofence population tracking, dedicated lane / route indication. |

Signal coordination conditions, speed enforcement, geofenced population management, dedicated lane / route utilization. |

Queueing information, congestion reporting, priority path use, dynamic tolling, congestion pricing. |

Dynamic modeling of transport space, movement optimization, congestion avoidance. |

| Gate Efficiency |

Reduce queueing, improve accuracy, avoid transaction failure, gate transaction speed, extend hours, and optimize labor. |

| Multi-unit manifest coordination, team-wide transport monitoring and coordination. |

Transaction-driven directional signage, queue entry/exit recording, queue-driven signal controls. |

Vehicle / equipment ID OCR, RFID, LPR; dynamic tare + fuel for weighing; digital hazmat placard; digital seal; dead vehicle in queue; reefer temperature / condition. |

Automatic transactions, off-terminal pre-processing, shift from “push” to “pull” processing, dynamic vehicle prioritization. |

Align “pull” transactions to terminal resource availability, paperless liability controls, paperless manifest, transactions. |

| Terminal Yard Efficiency |

Improve density and velocity, improve cargo handling equipment deployment, reduce cargo rehandling, reduce congestion. |

| Equipment queue management, report truck wait times, eliminate over-stows of moves in the queue. |

Area closures, area restrictions, dynamic routing signage. |

Mobile data terminal integration, geofenced density reporting, proximity to assigned equipment or location. |

Dray-off yard areas for pre-lodged transactions, dynamic intra-terminal route management, internal queue management. |

Equipment assignment optimization, awareness of upcoming moves to avoid over-stows, remote control operations. |

| Port Efficiency |

Improve the efficiency of total port visit, balance load between resources, respond to congestion events. |

| Train positioning and routing, vessel-lift bridge coordination. |

Equipment pool conditions, port-wide routing, terminal populations, rail crossing closures, train locations and movements. |

Bridge deck weight sensors, rail crossing equipment, lift-bridge conditions, berth utilization, rail yard utilization. |

Equipment inventories and demands, storage inventories, space available, transactions cleared for pickup, double-cycle opportunities. |

Port wide chassis management, empty management, rail car management, train scheduling and vehicle move timing. |

Source: WSP USA

Cybersecurity

While ITS provides opportunities to optimize port systems and improve operational performance, issues of security and privacy related to ITS can impact its potential benefits. Cybersecurity has risen out of the need to protect critical infrastructure and systems, and the information contained therein, from malicious attacks, unauthorized access, damage, and disruptions. The increasing use of ITS technologies exposes the U.S. maritime and freight sectors to cybersecurity vulnerabilities and highlights the need to safeguard ITS from cyberattacks.

A comprehensive approach to cybersecurity is necessary to counteract the growing risks of cyberattacks on ITS. Various federal agencies have cybersecurity initiatives dedicated to maintaining a secure, connected, and resilient transportation system:

- Vehicle – The National Highway Traffic Safety Administration (NHTSA) has pursued a layered approach focusing on identifying solutions to harden the vehicle’s electronic architecture against potential cyber-attacks and ensuring vehicle systems respond appropriately in the event of an attack.

- Infrastructure – The National Institute of Standards and Technology (NIST) lays out a broad path for reducing cyber risk and improving resiliency in their Framework for Improving Critical Infrastructure Cybersecurity. The Framework’s five Core Functions: Identify, Protect, Detect, Respond, and Recover provide a method to understand, evaluate, and reduce cyber risk. The USDOT had made it a priority to adopt and promote the use of the NIST Cybersecurity Framework within the transportation sector.

- Integration – The USDOT ITS Joint Program Office (ITS JPO) and its modal partners conduct research, development, and education activities on cybersecurity technical and policy mitigations. These efforts ensure that new technologies have security as an inherent part of their design and operations, providing a more unified approach to vehicle, device, and infrastructure security for the connected vehicle environment.

Key Elements

This module addresses key project development and systems engineering elements that can be adapted to specific needs and circumstances, whether users are at the early stages of the project definition process, such as determining project goals, or further along and seeking financing opportunities for an existing ITS project. This module focuses on three primary phases involved in project development that occur early in the systems engineering process: Planning-Design, Feasibility, and Financing; accompanied by a fourth Deployment phase to support an integrated ITS implementation approach.

Although the phases are presented sequentially in this module, the activities involved in each Project Development phase are dynamic, overlapping and can be iterative. As shown in Figure 2, Project Development phase activities can occur concurrently, within and between other phase activities and can loop back to previous efforts to continually improve the planning, feasibility, and financing strategy. Certain activities also may occur in multiple phases, such as stakeholder engagement and partnering, which are essential throughout the project development process.

Figure 2 : Project Development Process

Source: WSP USA

(Extended Text Description: This figure illustrates the interaction and interconnectedness of each component associated with the ITS project development process. Components are grouped by the following project phases; planning-design phase, delineated in yellow, feasibility phase, delineated in blue, and financing phase, delineated in green. The figure illustrates that the activities involved in the Project Development Process are dynamic, overlapping, and iterative. Certain components, such as stakeholder engagement and partnering, interact with more components than others.)

Return to top ↑

Planning and Design

Opportunities to implement ITS solutions should be considered as early as possible, in both the more comprehensive strategic planning process and during the planning for a specific transportation improvement and/or ITS project.

Regional ITS architecture is a broader product of the planning process that covers all ITS projects in the region. A regional ITS architecture supports the initial identification and scoping of an ITS project based on regional needs. While it is important to ensure ITS projects are considered in the regional context, this module primarily focuses on the efforts identified in the SE approach “V” processes that apply to specific ITS port projects.

Refer to the regional ITS architecture, typically managed by the MPO, or the applicable portions of the ARC-IT [National ITS Reference Architecture] to facilitate the integration and coordination of compatible ITS initiatives across a region, including those that involve port operations. The regional ITS architecture helps to ensure that related ITS projects are implemented more efficiently and travelers experience seamless transportation services as they travel across multiple jurisdictions. For an overview of National and Regional ITS Architecture, refer to ITS ePrimer Module 2, “Systems Engineering”.

Project Goals and Objectives

Defining the mission and vision are critical guiding principles that provide focus in the ITS planning process. Examples of port mission statements as they pertain to ITS programs include:

- Provide the highest quality and most efficient intermodal freight services for economic prosperity,

- Operate and manage an optimized, integrated transportation network by delivering high quality services for efficient and reliable movement of freight, and

- Provide high quality, adaptive, and integrated freight mobility technology solutions that meet the needs of all users.

ITS goals and objectives are centered on enhancing the safety, security, mobility, and environmental impact of transportation systems in and around the port community. The most critical factor in defining the mission, vision, goals and objectives is active engagement of stakeholders that will be impacted by or oversee the deployment and operation of ITS. Table 3 provides example goals as they relate to port ITS applications in Integrated Corridor Management (ICM) initiatives.

ICM is a multi-year USDOT initiative to develop and demonstrate innovative strategies that use ITS to manage traffic congestion and effectively move people and goods through major corridors. ICM focuses on the integrated management of a corridor as a system rather than the management of the individual transportation networks (e.g., rail lines, bus routes, arterials, freeways) within a corridor. Additional information about the ICM Initiative can be found at https://www.its.dot.gov/research_archives/icms/index.htm.

Table 3 : Port ITS Goals Related to ICM

| Goals |

Importance to Ports |

| Facilitate On-Time Pick-Ups and Deliveries |

- Contracts for freight services often include very specific time windows for pick-ups and deliveries.

- Commercial drivers are regulated by Federal hours-of-service rules which limit the hours each day that drivers can be on-duty and driving, and any delays in a driver’s schedule can impact their availability to work later in the day or week.

|

| Improve Travel Reliability |

- Reliable travel times allow ports to accurately manage loads and equipment, schedule pick-up and delivery times and plan for mandated driver rest breaks.

|

| Reduce Fuel Consumption |

- Medium- and heavy-duty trucks account for 22 percent of transportation-related Greenhouse Gas (GHG) emissions, which equates to roughly 6 percent of total U.S. GHG emissions.

- Idling trucks can consume anywhere from 1/2 to 1 gallon per hour.

|

| Reduce Non-Revenue-Generating Labor Hours and Vehicle Maintenance Costs |

- The trucking industry faces a significant driver shortage. The driver shortage is pushing driver wages higher, making the non-revenue-generating labor hours that drivers spend stuck in traffic costlier.

- The highest industry costs per mile for vehicle repair and maintenance are experienced by less-than-truckload carriers whose operations are often focused on pick-up and delivery in congested urban areas.

|

| Increase Safety |

- Research that compared crash involvement rates for medium-duty (10,001 - 26,000 lbs.) and heavy-duty (26,001 lbs. and greater) trucks found the highest crash rate index for medium-duty trucks in the central counties of metropolitan areas with populations over 1 million, areas where most port facilities are located.

|

Source: Integrated Corridor Management and Freight Opportunities, https://ops.fhwa.dot.gov/publications/fhwahop15018/index.htm.

Stakeholder Engagement

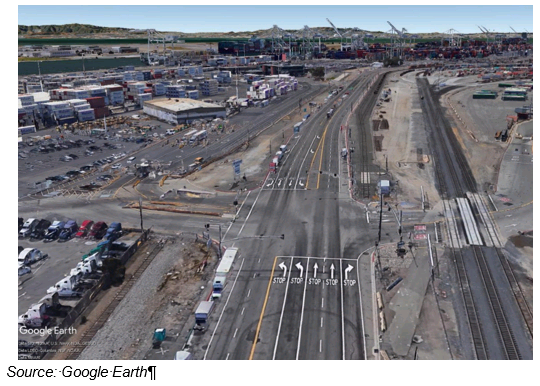

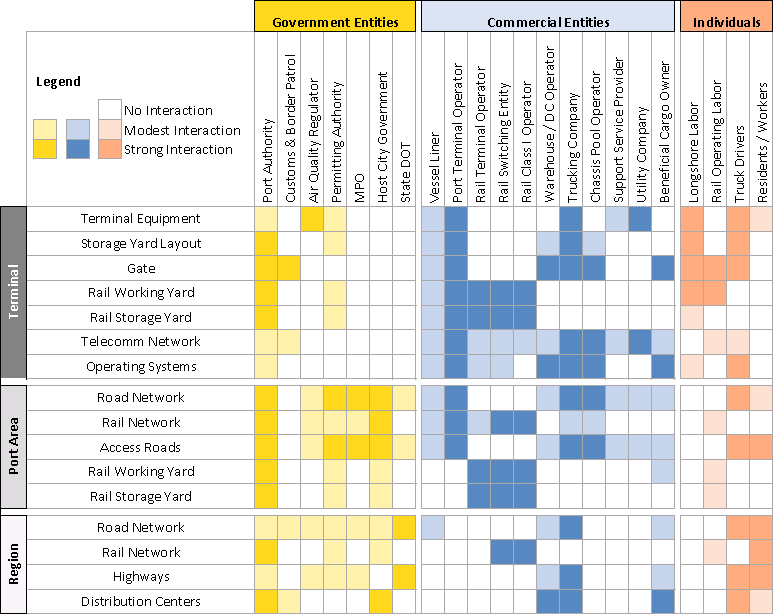

Stakeholder input is crucial in defining the objectives, goals, performance measures, and user needs for each ITS application. In the context of the port this includes all entities that are responsible for the safe, secure and efficient movement of goods and people. Figure 3 shows the complex network of interaction between major project elements and stakeholders in the typical port.

The primary actors on the port’s road and rail system include trucking companies, Class I rail operators, rail switching entities under “Commercial Entities,” and truck drivers under “Individuals.” These stakeholders’ and users’ needs will be central in preparing for any ITS deployment. Under Project Elements, the terminal’s gate and rail yards, telecommunications network, and operating systems may be impacted by ITS, and the port area transportation network will be the physical home of most ITS infrastructure. Figure 3 highlights where the interests of the key ITS entities intersect with these project elements, and how these Project Elements are influenced by other stakeholders.

The port area transportation network can come under the influence of the port authority, air quality regulators, permitting authorities, MPOs, the host city’s government, quasi-governmental development corporations, and state Departments of Transportation (DOTs). These landside transportation project elements are also influenced by a range of private sector entities, including vessel lines, terminal operators, warehouses, trucking and rail companies, chassis pool operators, support service providers, utility companies, and, of course, BCOs, who generate truck and rail movement demands.

The terminal operator has the strongest influence over the working of the terminal elements. The truck driver must interface with the terminal operator’s operating systems to process transactions, with the gate system to enter or leave, with the storage yard layout to get to the right storage spot, and with the terminal equipment to receive or deliver the cargo. The port authority has a role in gate and storage yard design. U.S. Customs and Border Patrol has a strong role in the functioning of the gate, as it represents a bonded customs and transportation security boundary. The vessel liner is the terminal operator’s primary customer, driving virtually all commercial decisions.

Active engagement with these stakeholders provides the opportunity for them to contribute throughout the scoping, planning and development process. This includes contributing to the ITS mission, vision, goals and objectives; the identification of user needs; and the review and concurrence on outputs of the planning process at critical decision points. Stakeholder engagement is also intended to provide visibility into the process, sustain participation in necessary data exchange, and foster ownership of the outcomes.

Figure 3: ITS Project Elements and Related Stakeholders

Source: WSP USA

(Extended Text Description: The matrix shows the interaction between major project elements and stakeholders in the typical port. Stakeholders are grouped into public agencies, private enterprise, and individuals. Project elements are grouped by the marine terminal, the port area transportation network, and the region in which the port is located.)

Partnering

Engage private sector entities as partners in the ITS planning process to ensure that resulting plans meet the needs of shippers and merchants and are consistent with supplier’s capabilities. Involving private enterprise in port-ITS planning activities presents opportunities for additional funding sources. Examples of partnerships with private entities that have helped facilitate the deployment of transportation technologies include:

- Traffic signal data sharing – Companies are beginning to seek traffic signal data from public agencies for purposes of resale and/or utilization in an application meant for public consumption. One common approach is to “extract” signal data from a central advanced traffic management software (ATMS) platform most commonly provided by signal system vendors. Once extracted the data is transmitted over the internet to secure servers at one of the company locations where they can manipulate the data as needed.

- Piloting new technologies - Developers of advanced technologies sometimes enter partnerships with state and local jurisdictions to pilot emerging technologies. As an example, with this type of arrangement a technology provider may provide a port owner with equipment to deploy on their fleets. This provides the port with the functionality of the technologies. This also allows the technology provider with opportunity to assess the operational performance and user acceptance of the equipment in a live operational environment.

For more information on the goals, and strategies of private and public sector ITS freight applications, and examples of ITS freight applications and benefits to stakeholders, refer to ITS ePrimer Module 6: Freight, Intermodal, and Commercial Vehicle Operations.

Existing Conditions

Identifying the optimal ITS solution requires an understanding of the port’s capabilities and constraints, and the operation of the regional road network. Data should be collected to the level that ensures the decision makers have sufficient information about port and local/regional transportation performance, operations, and community priorities. Table 4 provides a sample categorized list of data that could be needed for port ITS projects.

This data may be readily available from port and other local/regional agency staff, project stakeholders, or from secondary sources such as publications. The data collection effort presents an opportunity for multiple organizations to merge some, or all, of their transportation-operations data, providing for a more thorough understanding of ITS system impacts and the ability to coordinate transportation improvements and operations. For more information on supporting data collection technologies for successful ITS, refer to Module 9, “Supporting ITS Technologies.”

Table 4: Sample Types of Project Data

| Strategic |

Infrastructure |

Operational |

System Performance |

Financial |

| Regional ITS Architectures |

ITS Infrastructure Inventory |

ITS Field Devices and Equipment Inventory |

Historical and Forecasted Port and Inland Transport Carrier Volumes |

Congestion Costs |

| Port Planning Documents |

Site Boundaries and Adjacencies |

Truck and Rail Carrier Schedules and Operational Patterns |

Historical and Forecasted Traffic Forecasts on Identified ITS Corridor(s) (Freight Movement on Interstate) |

Lifecycle Costs |

| MPO Transportation Plans and TIP |

Maps and Aerials of Existing Sites, Facilities and Infrastructure |

Port Facilities Operating Schedules, Requirements and Patterns |

Port Performance Statistics (Truck and Rail Turn Times, Gate Processing) |

Financial Assistance Requirements |

| Statewide Transportation Improvement Program Documents |

Truck and Rail Access in Port Area, Inland Rail and Highway and Arterial Networks |

Terminal Equipment Deployment Patterns |

Mobility Statistics (Travel Speeds, Delay Times, Levels of Service) |

Contracting Requirements |

| State/Local Freight Plans |

Local Designated Truck Routes and Weight Limits |

Transaction and Resource Supply Data |

Reliability Statistics (Travel-Time Index, Planning-Time Index) |

Tariffs, Tolls and Other Transportation Fees |

| Land Use Studies |

Environmental Site Assessment Reports |

Labor Deployment Rules |

Safety Statistics (Accidents, Fatalities, Injuries, Locations and Contributing Factors) |

Historical Transportation Infrastructure Capital Costs |

Source: WSP USA

Prepare an inventory of existing and planned ITS infrastructure and other technologies to identify current conditions, resources available for regional integration, and constraints and opportunities for sharing of information with local and regional partners. Determine existing operational conditions along the port area and regional transportation network as they relate to safety, mobility, and reliability. This inventory also provides a baseline to gauge existing conditions against identified user needs.

Table 5 provides an example of ITS-related elements that may be included in the inventory process. The inventory process is best facilitated through an interview process with port and terminal staff, DOTs, rail operators and other operational stakeholders.

Table 5: Example ITS Inventory Elements

| Element |

Item |

| Technological |

- Communications infrastructure

- Freight traceability and security systems

- Facility access security systems

- Port logistics management systems

- Traveler information systems

|

| Institutional |

- Organizational structure

- Operational policies

- Operational constraints

- Funding sources

|

| Operational |

- Performance targets

- Priority cargo and equipment movements

- Systems integration

- Security protocols

|

| Cross-Sectional |

- Port ITS System Architecture

|

Source: WSP USA

Project Drivers and Needs

Identification and documentation of needs is derived from active engagement of stakeholders and is intended to identify the port’s operational challenges, their impacts on carriers serving the port and the traveling public, and potential strategies to overcome them. This process needs to be structured in a manner so that it does not just look at the operational challenges at the surface, but rather examines the root causes to help derive the optimal ITS solution. Table 6 provides an example of grouping of port operational challenges and user needs.

At this point, hold off on identifying possible solutions as technologies often advance during the project definition process. Apply the Systems Engineering approach as described in Module 2, “Systems Engineering,” which focuses on fully defining the problem, identifying user needs and documenting requirements prior to forming alternatives.

Table 6: Analysis and Building of Needs

| User Need |

Underlying Cause |

| Improve travel time reliability in accessing port |

- Traffic signals owned and operated by multiple jurisdictions are not coordinated

- Outdated timing plans

- Outdated equipment including controllers

|

| Reduce queueing at port entrance |

- Limited ability to manage truck flow at port

|

| Mitigate truck infringement on residential roads |

- Limited ability to manage truck routing

- Zoning ordinances vary by jurisdiction

- Inadequate information for truckers

|

Source: WSP USA

Alternatives Development and Analysis

Once the existing conditions, project drivers and needs have been identified, generate a range of practical, effective project alternatives and strategies that will fulfill the project goals and objectives. In forming project alternatives, provide sufficient detail to facilitate the measurement of impacts and performance of each alternative later in the project definition process.

The development of alternative ITS strategies provides the opportunity to connect operational needs to the most viable ITS solution. ITS alternatives should be documented as one- to two-page briefs so that they are available for future funding alternatives, including grants. ITS alternatives might include the following:

- Project description;

- Relation to the ITS mission and vision;

- System goals and objectives;

- System requirements;

- Data storage, generation and sharing activities;

- Earliest potential start date;

- Estimated duration of project development activities;

- Capital funding requirements;

- Lifecycle operational costs;

- Operational challenges to be addressed;

- Anticipated benefits;

- Potential risks;

- Impacts on the organizations;

- Interactions with other systems;

- Requirements and impacts on regional partners; and

- Operational responsibilities.

Refinement of Alternatives

Refining ITS alternatives identified in the exploration of concepts to a point where they are ready to move forward to the design phase is primarily accomplished in the development of the Concept of Operations (ConOps), and the definition of System Requirements. Develop or update a ConOps that provides an overview of the proposed project or system from the viewpoint of the user as described in Module 2, “Systems Engineering”.

Key activities in the requirements definition process that move the overall concept closer to design are:

- Identification and documentation of and analysis of system requirements,

- Validation and management of system requirements,

- Development of a system verification plan, and

- Definition of a system acceptance plan.1

High-Level and Detailed Design

Designing a port ITS project typically involves preliminary engineering of infrastructure, environmental analysis, permitting, and ITS software and hardware design using a formal Systems Engineering process as described in Module 2, as well as in 23 CFR Part 940 – ITS Architecture and Standards. Guidance and resources for designing and implementing ITS projects are available at Federal Highway Administration’s (FHWA’s) ITS Architecture Implementation Program site.

Return to top ↑

Feasibility

The port industry is accustomed to gradual change that enhances performance without major disruptions to operations. Even when improvements to performance or efficiency are demonstrably clear, stakeholders often respond cautiously, recognizing the complexity, sophistication, and essential viability of the existing system.

The cargo handling paradigm can, and must, continue to evolve, through careful integration of new tools and techniques that improve performance without degrading the excellence that has already been achieved. Technology vendors from outside the maritime industry can offer innovations, but these ideas must be subjected to robust feasibility analysis to avoid deployment failure.

A feasibility analysis on the deployment of ITS infrastructure includes the following steps:

- Assessing how ITS alternatives interact with stakeholders’ resource and demand balance.

- Quantifying existing and proposed performance of these resources in terms of effort, timeliness, and reliability. For example, an ITS project to improve access to the port’s centralized chassis yard may impact truckers and terminal operators differently depending on their location within the port.

- Identifying the current state of port and freight transportation operational practices, of commercial liability, of organized-labor deployment, and of existing positions of authority and responsibility for the specific area of concern.

- Determining whether any of these constraints will impact the operational efficiency or cost effectiveness of the ITS alternatives for the port.

Initial Assessment

Human Factors

Two human resource issues that need to be addressed during the assessment of potential port ITS projects are (1) the need for additional staff, and (2) the staff training that will be required to operate and maintain new systems. ITS provides the opportunity to expand operational capabilities of a port, but consideration must be given to whether these deployments will necessitate additional staff for routine operations and for preventative and emergency maintenance of the systems that are deployed.

Further, it is important to understand that the deployment, operation, and maintenance of ITS may require skill sets that a port may not currently possess. The port owner will need investment in building the technical capacity of staff to not only ensure that the benefits of the deployed systems are maximized, but to ensure they are properly maintained to maximize the lifecycle of the systems.

Impacts

There are a wide-range of institutional, operational (safety, mobility), environmental, and economic impacts that may result from the deployment and operation of a port ITS project. ITS can provide benefits to an existing system that successfully moves millions of containers and tons of cargo into and out of the nation’s ports each year. Potential benefits for ports, terminal operators and freight transportation providers, include:

- Safety - Measured through changes in accident rates or other surrogate measures such as equipment interchange conflicts, or workers’ compensation claims.

- Mobility - Measured in travel time or delay savings, as well as travel time savings, on-time performance, and travel-time reliability.

- Efficiency - Represented through increases in capacity or level of service within the port and terminal, as well as along existing road networks or freight rail systems.

- Productivity - Measured in terms of cost savings to transportation providers, terminal operators, or shippers.

- Energy and Environment - Typically documented through fuel savings and reduced pollutant emissions.

Risks and Mitigations

To understand how ITS can be successfully implemented in the port environment, it is important to also understand the potential risks and challenges that ITS applications might need to overcome.

Responsibility and Authority: The movement of cargo to, from and within port terminals requires a complex exchange of private and public agency authority and responsibility. There is usually no commercial relationship between the terminal operators and either the truck driver, the trucking company, or the BCO. The isolation between BCOs, who have the authority to schedule landside moves, terminal operators, who are responsible for serving those moves, and truckers, who perform the moves, will need to be addressed to leverage the interconnectivity of ITS.

Random Demand: The terminal operator is frequently faced with random demands for landside transport from the truck driver or BCO. The BCO’s decision to deliver or retrieve cargo at the terminal is generally made without any communication with the terminal operator, and with no understanding of the terminal’s current or expected state or service capability. On occasion, and sometimes with little warning, the terminal operator may need to constrain landside service to have capacity for waterside operational demand. This variability in terminal landside behavior can impact road/terminal ITS integration as truck movements in and out of the terminal are restricted. The increasing use of blockchain technology and digital platforms to connect port users and better manage supply chains should improve the visibility into landside cargo demand in the future.

Problem Resolution: Most terminal gates have “trouble service” areas where truck drivers can be removed from the stream to resolve transaction problems on their own time. Typically, trouble services are neither centrally monitored nor controlled, which can make them invisible to potential ITS solutions. Problem resolution areas will need be taken into account during the planning process for port ITS projects.

Waterfront Labor: Terminal operators employ trained stevedores to work ships and longshoremen to handle cargo in the terminal yard and gate. In most major ports, these workers are members of strong unions that have negotiated rigorous contracts with waterfront employers. These contracts reflect the long history of labor relations on the waterfront and are not easily changed. Waterfront labor and their employer representatives should be jointly consulted during stakeholder engagement efforts to improve the acceptance or net effectiveness of ITS projects.

Freight Security: One of the primary goals of transporting cargo has always been maintaining freight security: preventing damage, theft, or pilfering. Container contents, and the logistics surrounding container movement, are closely protected data. A data security program that includes ITS should be developed and implemented that provides guidance to those who will oversee the acquisition, installation, operation, and maintenance of ITS to ensure the ITS solution does not undermine freight security or confidentiality.

Transportation Security: Since September 11, 2001, transportation security has been a major driver of changes to port operating practices. In many ways, freight security and transportation security are in conflict because container secrecy reduces the odds of catching contraband or weapons. Over the years, a modus vivendi has been worked out that meets the needs of both freight and port security, and any new technologies or systems must work within the current security framework. Port ITS projects aimed to improve efficiency by improving transactional data visibility must take transportation security requirements into account.

Cyber Resiliency

The first step in fostering cyber resiliency is to understand the relationships and interdependencies of a port’s business processes, networks, systems, and applications. This will help inform what redundancies and preparations are required to protect against a cyber-attack and enable a swifter recovery. The following organizations have published guidance and/or resources that will help ports facilitate cybersecurity and resiliency efforts.

The Coast Guard provides a variety of information and resources concerning maritime cybersecurity through USCG Homeport: Cybersecurity.

The American Bureau of Shipping (ABS) has provided a series of Guidance Notes on Cybersecurity and resiliency matters for vessels, ports, and other shoreside facilities. ABS provide an approach to measuring cyber risk - the FCI Cyber Risk™ equation, which can be found at ABS Maritime Cyber Security.

The International Maritime Organization (IMO)’s Guidelines on Maritime Cyber Risk Management provides high-level recommendations on maritime cyber risk management to safeguard shipping from current and emerging cyber threats and vulnerabilities, which includes functional elements that support effective cyber risk management.

Project Evaluation Approach and Recommended Project

There are various methodologies that can be used to select potential ITS projects. Although individual ports may have their own methodology for evaluating and recommending projects, there are general steps that may be taken with regards to evaluating ITS projects:

- Screening – ITS projects should be screened to determine their basic feasibility. Key factors to be considered in the screening could include: user needs and functional requirements, user acceptance, consistency with mission and vision, potential deployment or operations challenges, and likelihood of having available funding.

- Technical evaluation and ordering – This process entails a qualitative and quantitative assessment of projects against criteria related to the goals and objectives, and agreed to by stakeholders. Based on the assessment, projects would then be ordered per their score. Ideally high-priority projects will be those that:

- Address the operational needs of the port and surrounding transportation network,

- Are the most technologically and operationally feasible,

- Provide the highest value in terms of performance and cost,

- Have the least impacts on existing terminal operations,

- Minimize additional staffing and training requirements,

- Minimize additional operations and maintenance funding, and

- Are sustainable by the port and their operational partners.

- Review – Technical advisory committee review and concurrence on the accuracy of the evaluation.

- Selection – Project selection is a critical step that entails concurrence from stakeholders. This is the point at which the port owner will begin to try and secure adequate funding for the project(s).

The process of evaluating and recommending ITS projects will be well-served by the establishment and utilization of a technical review committee that includes a diverse range of port stakeholders.

Project Prioritization

It is possible that a port owner may not have the funding to deploy all the desired ITS solutions at one time. Therefore, it will be necessary to prioritize projects based on the overall ITS vision. Factors to be considered in the prioritization of projects include:

- Urgency of need for the project – Is the project replacing or supporting a critical system or function that is failing or near the end of its useful life?

- Benefit/cost (B/C) ratio of the project – What is the expected B/C ratio of the project?

- Sequencing as related to other projects – Is the project required to enable the functionality of other projects (e.g., communications infrastructure)?

- Portion of project cost - Is the ITS application a component of a high priority project?

- Funding availability – Is there adequate funding to support the planning, development, operations, and maintenance of the desired project. Not accounting for adequate funding to maintain the deployment of technologies is a common mistake.2

Return to top ↑

Financing

Funding for ITS has become an integral part of established transportation investments in the U.S., often augmenting the construction of hard transportation infrastructure. ITS projects are an affordable solution to enhance safety and mobility in comparison to building new roadways and bridges. The comparatively low-cost technology can offer investors a high return on investment (ROI) as measured in safety, travel time reliability, throughput and quality of life. The monetary benefits from ITS solutions continue to stimulate public and private investment in these technologies.

The broad array of public and private sector financing and funding options for ITS projects allows port owners to take advantage of multiple investment opportunities. To do so, port owners should perform the following steps:

- Review government funding mechanisms currently used for ITS projects, their institutional and legal framework, financing arrangements, requirements including timelines and procedures, and other key features.

- Identify multiple alternative funding solutions and distinguish between near-term opportunities and long-term financial strategies to support the recommended ITS project.

- Consider which strategies will offer the best solution in view of the port’s mission and the specific ITS project objectives.

- Take into account how funding and financing options such as private activity bonds (PABs), lease agreements, and public private partnerships (P3) could impact the compatibility and continuity of the recommended ITS project.

Financial Plan

After evaluating the advantages and disadvantages of public, hybrid, and P3 financial alternatives, develop a financial plan and model to determine the most appropriate structure for the ITS project. The funding structure should include an assessment of the economic, social and operational value of the port ITS project.

Miami-Dade County/PortMiami Truck Gate

In 2018, Miami-Dade County was awarded a $7 million INFRA grant to replace two cargo terminal gates at PortMiami with automated systems that use OCR to read data from trucks traveling towards Port Boulevard along the PortMiami tunnel. The real-time data will be electronically transferred to the gate, providing terminal operators advance notification of impending truck arrivals to terminal operators. The project will improve terminal fluidity, gate processing, and truck turn times.

A detailed project finance and cash flow model should be developed and incorporate current and projected operating revenues, initial and maintenance capital expenses (CapEx), operating expenses (OpEx), and outstanding debt service. Ensure the model has the flexibility to consider incremental revenues, OpEx costs, and debt service associated with the project. Modeling OpEx costs are particularly important since the ongoing day-to-day costs for some port ITS projects can exceed the funding necessary for the initial deployment. The pace of technological advancement and periodic staff training can further compound the ITS operational costs.

The financial plan should include:

- Financing and debt objectives;

- Debt profile including re-structuring/refunding opportunities for existing debt;

- Projected CapEx, OpEx, and revenues and sources;

- Risk sensitivity analysis;

- Credit rating outlook and strategies; and

- Financing alternatives and P3 techniques that can be utilized in various combinations.

The overall result should be a comprehensive analysis and corresponding financing structure that supports the development, deployment and sustainable operation of the port ITS project.

Funding Sources

Federal

Federal funding change from year to year, as government revenue levels vary and federal appropriations fluctuate. There are various federal programs available to port owners at any given time. Table 7 summarizes the availability of select government funding programs at the time of this module version that specifically facilitate the delivery of port ITS projects. Access further details by clicking on the title of the government funding program in Table 7.

The majority of the programs fall under the Fixing America’s Surface Transportation Act (FAST Act), which funds surface transportation programs at over $305 billion for fiscal years (FY) 2016 through 2020. It is the first long-term surface transportation authorization enacted in a decade that provides long-term funding certainty for surface transportation. The FAST Act provides a range of new and existing funding opportunities to fund port-ITS initiatives.3

Table 7: Federal Government Funding Programs

| Program |

Summary Description |

Program and Project Size |

Max. Federal Award |

Key Eligibility Requirement for Port/ITS |

| ATCMTD |

Competitive grant for deployment of advanced transportation and congestion management technologies. |

$60M /yr. through 2020; Max. Size $12M |

50% of project cost |

State or local government or political subdivision thereof; or multijurisdictional group. |

| ITS |

Funding for the development of ITS infrastructure, equipment, and systems; and ITS research initiatives, exploratory studies, and a deployment support programs. |

$100M/yr. through 2020 |

80% of project cost |

Enhancement of the national freight system and support national freight policy goals. Limits use of funds for the construction of physical surface transportation infrastructure. |

| BUILD |

Competitive grant for enhancement of surface transportation infrastructure at local and regional level. |

Variable – Yearly. appropriation; Max. $25M |

80% of urban project, 100% of rural project |

Freight rail transportation projects, port infrastructure investments, and intermodal projects. |

| INFRA |

Competitive grant for highway and freight projects of national or regional significance. |

Max. $500M for freight through 2020; Min. $25M large project, $5M small project |

60% of project cost |

Acquisition of equipment, and operational improvements directly related to improving system performance. |

| STBG |

Formula funding for States and MPOs for priority transportation projects. |

Approx. $12B/yr. through 2020 |

80% of project cost |

Projects that facilitate direct intermodal interchange, transfer, and access of freight into and out of a port terminal. Includes installation of V2I communication equipment. |

| NHFP |

Formula funding for States to improve movement of freight on National Highway Freight Network. |

Approx. $1.4B/yr. through 2020; Max. 10% freight |

80% of project cost |

Project must be identified in a freight investment plan included in the State’s freight plan. |

| CMAQ |

Formula funding for States, MPOs and local governments for transportation projects and programs to help meet the requirements of the Clean Air Act. |

Approx. $2.45B/yr. through 2020 |

80% of project cost |

Verified technologies for non-road vehicles and non-road engines that are used in port-related freight operations located in ozone, PM10, or PM2.5 nonattainment or maintenance areas. |

| TIFIA |

Financing assistance for ITS and surface transportation projects, certain freight rail projects, intermodal freight transfer facilities, and certain projects inside a port terminal. |

$300M/yr. through 2020; $15M ITS projects4 |

49% of project cost

(TIFIA max.) |

Projects must be identified in the relevant State Transportation Improvement Program. |

| RRIF |

Financing assistance for railroad equipment, facilities and infrastructure including positive train control systems. |

Up to $35B in loans, up to $7B for non-Class 1 carrier projects |

100% of project cost |

Loan recipients required to pay a credit risk premium. |

| PABs |

Tax-exempt financing issued through a public conduit for privately developed infrastructure. |

$15B in total allocation; Approx. $6B remaining |

100% of project cost |

At least 95 percent of bond proceeds to be expended within a 5-year period. |

Source: FHWA, Build America and USDOT

Virginia Port Authority TRS Expansion and Automated Data Model

In 2017, the Virginia Port Authority was awarded a $1.55 million ATCMTD grant to design, implement, and deploy a second-generation TRS at the Port. The project is comprised of three technological components:

- The installation of RFID readers at all entry and exit gates at the Richmond Marine Terminal, Portsmouth Marine Terminal, and Virginia Inland Port;

- A cloud based TRS that is integrated with the Inventory Management System and RFID readers at each facility; and

- A data model for standardizing and providing real-time status updates to truck dispatchers through their Truck Management Systems.

The TRS is based on a Data Subscription Model to get information from truckers to other supply chain stakeholders through a common cloud-based system across all the Port’s marine terminals.